Behind the Scenes: How Halifat's Aluminium Manufacturing Process Works

In the competitive world of public transportation manufacturing, Halifat has distinguished itself through an unwavering commitment to innovation and quality. At the heart of this distinction lies their proprietary aluminium body construction technique—a manufacturing approach that has been refined over decades to deliver buses that are lighter, stronger, and more durable than conventional alternatives.

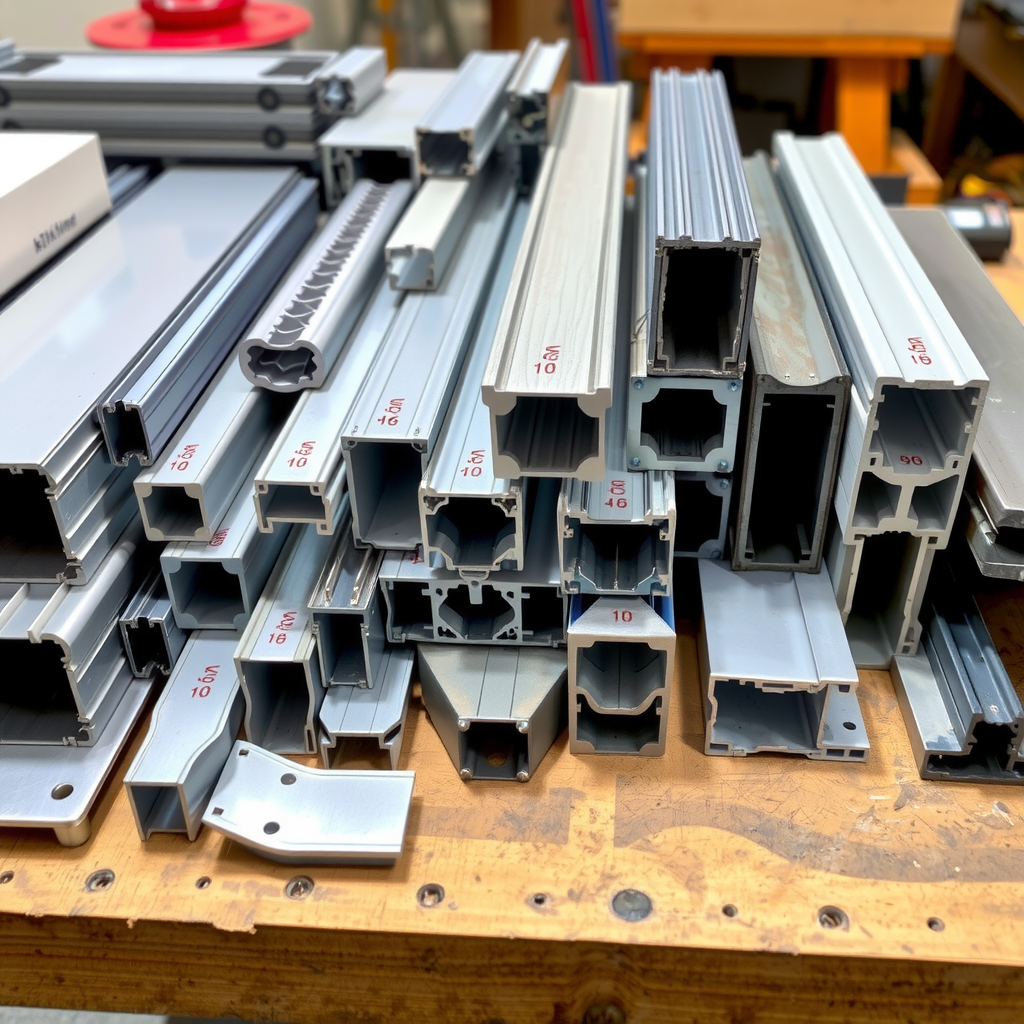

The Foundation: Specially-Moulded Extrusions

The journey of every Halifat bus begins with specially-moulded aluminium extrusions. Unlike standard off-the-shelf profiles, these extrusions are custom-designed to meet the exact specifications required for optimal structural integrity and weight distribution. Each profile is engineered using advanced computer-aided design software that accounts for stress points, load-bearing requirements, and thermal expansion characteristics.

"The extrusion process is where the magic begins," explains Marcus Chen, Chief Manufacturing Engineer at Halifat. "We're not just using aluminium because it's lighter—we're using it because we can shape it precisely to create profiles that would be impossible with traditional steel fabrication methods."

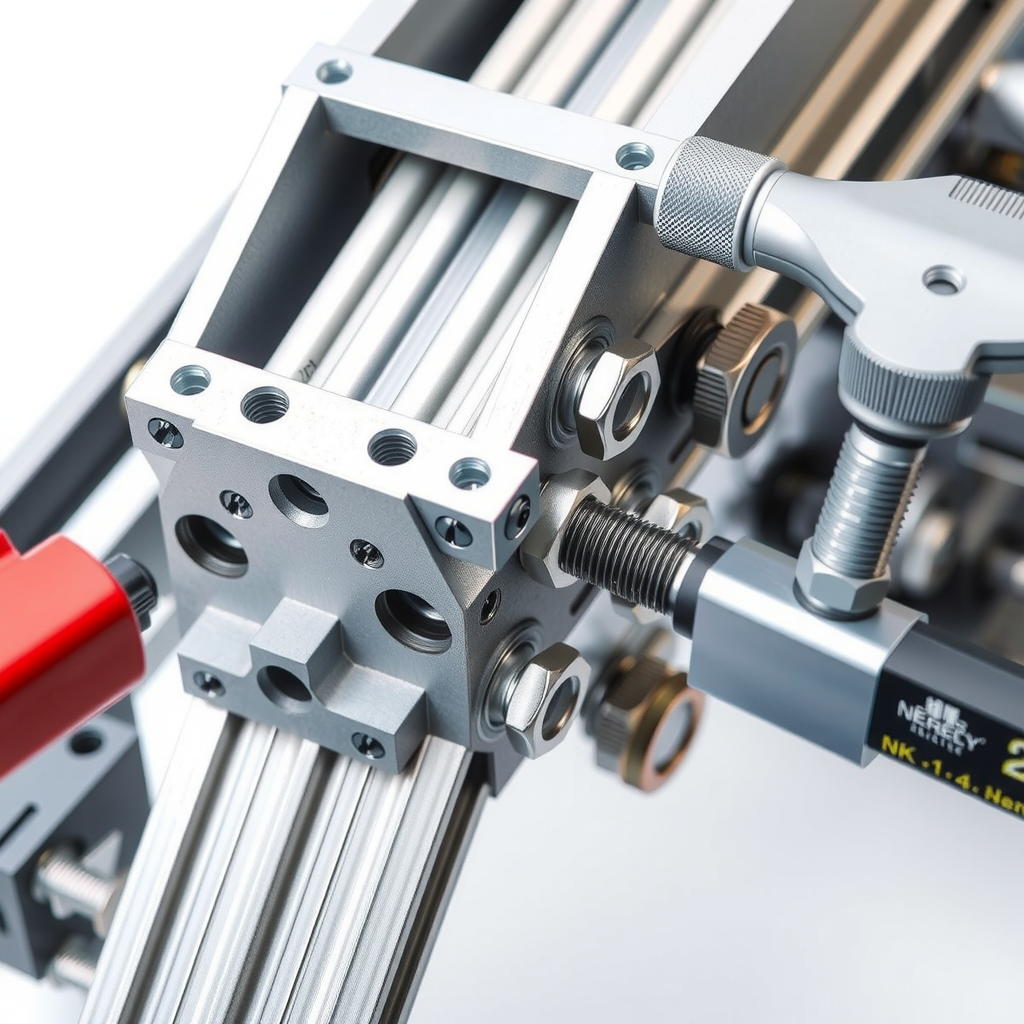

The Bolted Gusset System: Engineering Perfection

What truly sets Halifat apart is their innovative bolted gusset system. Rather than relying on welding—which can create weak points and stress concentrations—Halifat employs precision-machined gusset plates that are bolted to the aluminium extrusions. This approach creates joints that are not only stronger but also more consistent and easier to inspect for quality assurance.

Key Advantages of the Bolted Gusset System

- Faultless Joints:Each connection point is engineered to distribute stress evenly across multiple bolts, eliminating single points of failure

- Consistent Quality:Bolted connections can be precisely torqued to specification, ensuring uniform strength across every vehicle

- Serviceability:Unlike welded joints, bolted connections can be inspected, maintained, and even replaced if necessary

- Thermal Stability:Avoiding heat-affected zones preserves the aluminium's material properties throughout the structure

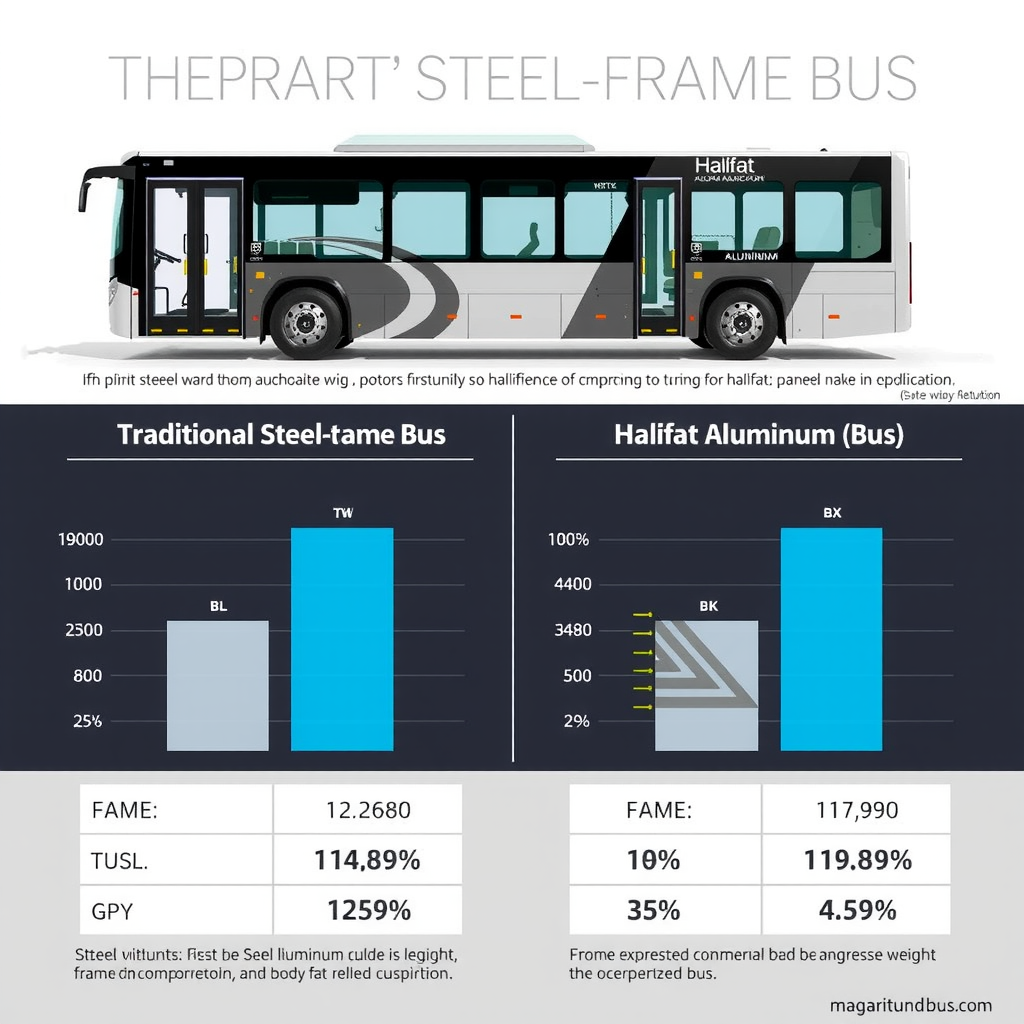

The 18% Weight Reduction Advantage

One of the most significant benefits of Halifat's aluminium construction approach is the substantial weight reduction compared to traditional steel-framed buses. Through rigorous testing and real-world validation, Halifat has documented an average weight reduction of 18% across their vehicle lineup.

This weight reduction translates directly into operational benefits for transit agencies. A lighter bus requires less energy to accelerate and maintain speed, resulting in improved fuel efficiency or extended range for electric variants. The reduced weight also decreases wear on tires, brakes, and suspension components, lowering maintenance costs over the vehicle's lifetime.

"When you multiply that 18% weight savings across a fleet of hundreds of buses operating millions of miles annually, the economic and environmental impact becomes truly significant," notes Dr. Sarah Williams, Director of Sustainable Transportation Research at Metropolitan Transit Institute.

Enhanced Longevity Through Material Science

Beyond weight savings, Halifat's aluminium construction methodology significantly extends vehicle service life. Aluminium's natural resistance to corrosion means that buses maintain their structural integrity even in harsh operating environments—from coastal regions with salt air to northern climates where road salt is heavily applied during winter months.

The aluminium alloys selected by Halifat undergo extensive testing to ensure they meet stringent durability standards. Each batch of material is certified for composition, strength, and corrosion resistance before being approved for production use. This quality control extends throughout the manufacturing process, with multiple inspection points ensuring that every component meets specification.

From Raw Materials to Finished Vehicle: The Assembly Process

The transformation from raw aluminium to a completed bus body follows a carefully orchestrated sequence of operations. The process begins with the arrival of extruded profiles at Halifat's manufacturing facility, where they undergo precision cutting to exact lengths using computer-controlled saws that ensure tolerances within fractions of a millimeter.

Precision Cutting

Extrusions are cut to exact specifications using CNC-controlled equipment

Gusset Installation

Precision-machined gusset plates are positioned and bolted to create structural joints

Frame Assembly

Components are assembled into complete frame sections using specialized jigs

Quality Inspection

Each joint and connection undergoes rigorous inspection and testing

Panel Integration

Aluminium body panels are attached to the structural frame

Final Assembly

Systems integration and finishing touches complete the vehicle

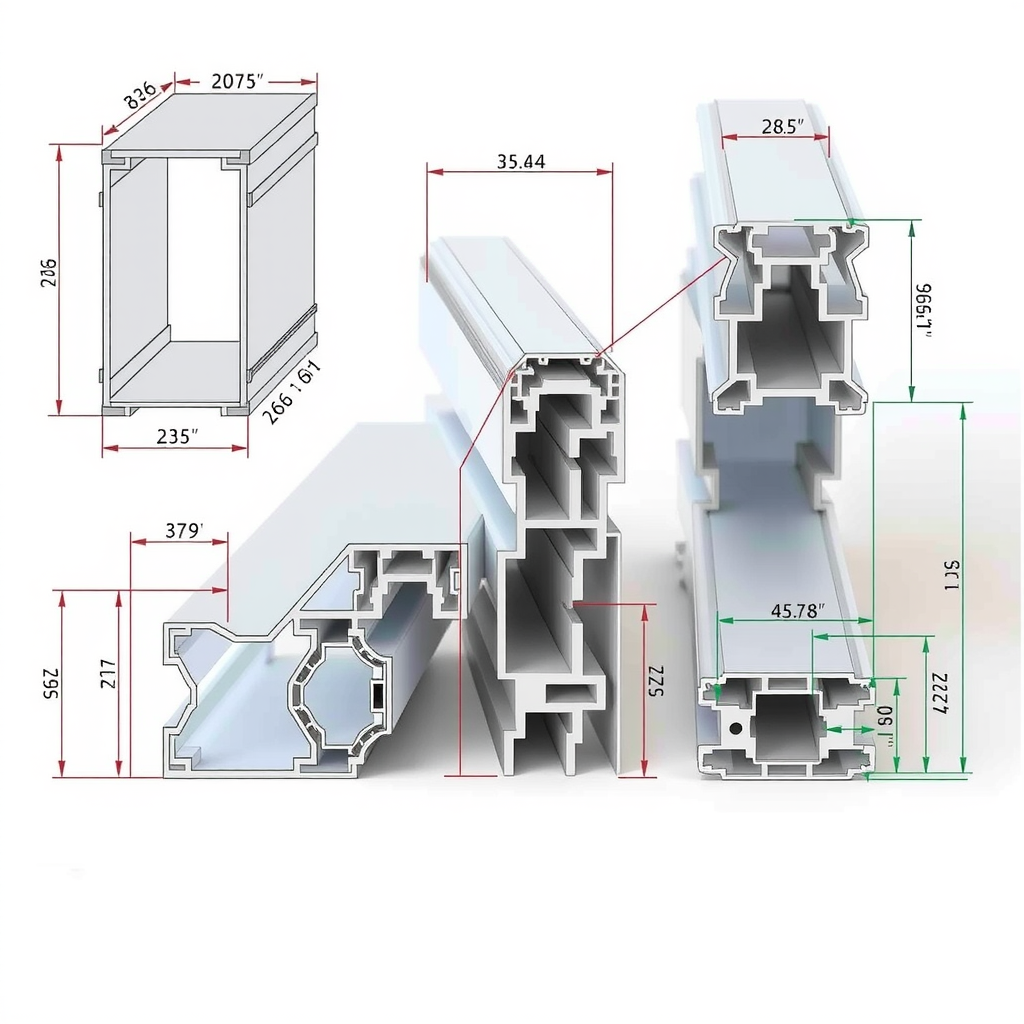

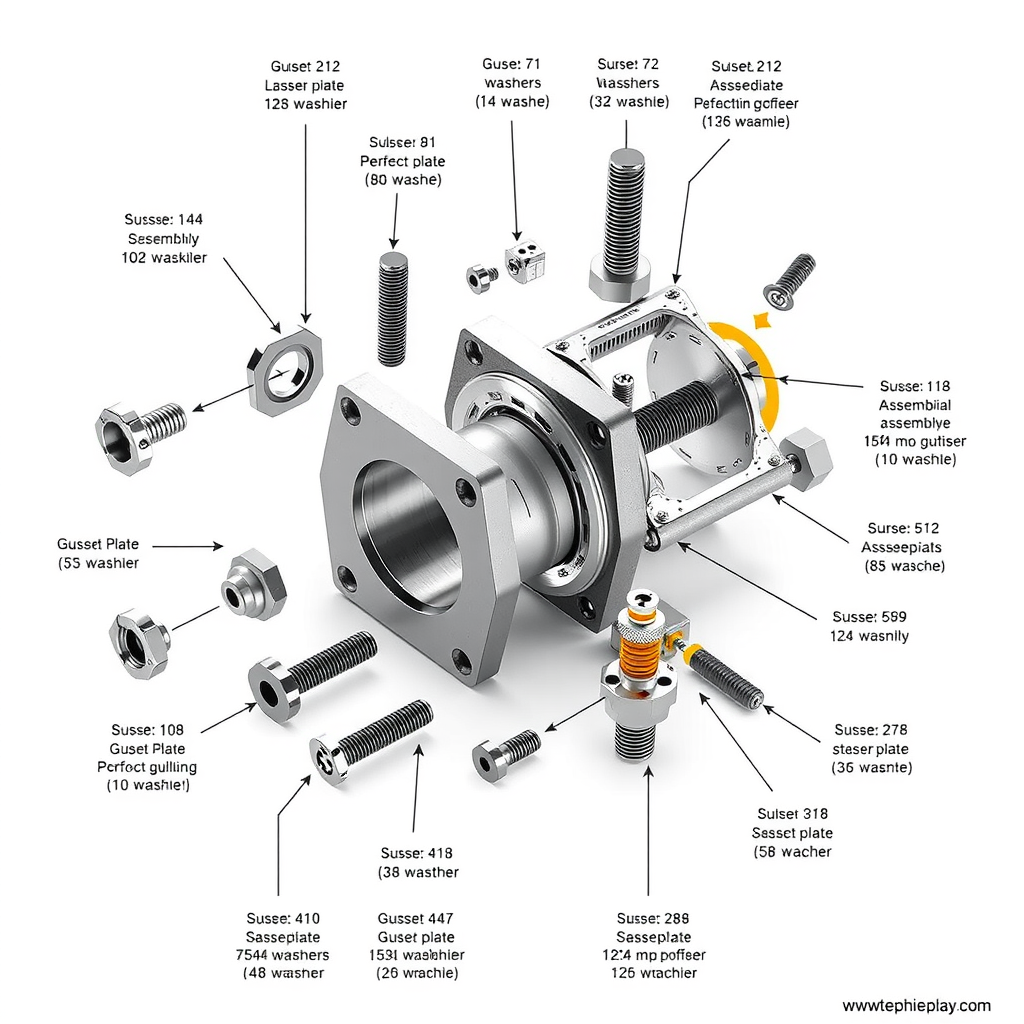

Technical Diagrams: Understanding the Structure

To fully appreciate the sophistication of Halifat's manufacturing approach, it's essential to understand how the various components work together to create a cohesive structure. The technical diagrams below illustrate key aspects of the construction methodology.

Cross-sectional analysis of custom extrusion profiles

Detailed view of bolted gusset joint assembly

Quality Control and Testing Protocols

Halifat's commitment to quality extends far beyond the manufacturing floor. Every vehicle undergoes comprehensive testing before leaving the facility. This includes structural load testing, where frames are subjected to forces exceeding normal operating conditions to verify safety margins. Non-destructive testing methods such as ultrasonic inspection and X-ray analysis ensure that every bolted joint meets specification.

Environmental testing simulates years of exposure to temperature extremes, humidity, and corrosive conditions in a matter of weeks. This accelerated aging process helps Halifat engineers identify potential issues before they can affect vehicles in service.

"We don't just build buses—we validate them," emphasizes Jennifer Martinez, Quality Assurance Director. "Every test we conduct is designed to ensure that our vehicles will perform reliably for their entire service life, which we design for a minimum of 15 years of intensive daily operation."

The testing data collected from these protocols feeds back into the design process, creating a continuous improvement cycle that has refined Halifat's manufacturing approach over multiple generations of vehicles.

Environmental Impact and Sustainability

The environmental benefits of Halifat's aluminium construction extend beyond operational fuel savings. Aluminium is infinitely recyclable without loss of properties, meaning that at the end of a bus's service life, the material can be reclaimed and reused. Halifat has established partnerships with recycling facilities to ensure that retired vehicles are properly processed, with aluminium components being recovered and returned to the manufacturing supply chain.

The manufacturing process itself has been optimized for minimal waste. Extrusion cutting is planned using sophisticated nesting software that maximizes material utilization. Offcuts and scrap are segregated by alloy type and returned to suppliers for remelting, ensuring that virtually no aluminium is wasted during production.

The Future of Aluminium Bus Manufacturing

As the transit industry continues to evolve, Halifat remains at the forefront of innovation. Current research and development efforts focus on further optimizing extrusion profiles using advanced computational modeling and artificial intelligence. These tools allow engineers to explore design variations that would be impractical to test physically, potentially unlocking even greater weight savings and structural efficiency.

The company is also investigating advanced aluminium alloys that offer improved strength-to-weight ratios and enhanced corrosion resistance. Some of these next-generation materials incorporate nano-scale reinforcements that could push the boundaries of what's possible with aluminium construction.

Looking Ahead: Innovation Pipeline

Halifat's engineering team is currently developing several breakthrough technologies:

- Smart structural monitoring systems that use embedded sensors to track frame integrity in real-time

- Hybrid construction techniques combining aluminium with advanced composite materials for specific applications

- Automated assembly systems using robotics and machine vision for even greater precision and consistency

- Modular frame designs that allow for easier customization and faster production cycles

Conclusion: A Tried and True Approach

Halifat's aluminium body construction technique represents the culmination of decades of engineering refinement and manufacturing expertise. The combination of specially-moulded extrusions and bolted gusset systems creates structures that are simultaneously lighter, stronger, and more durable than conventional alternatives.

The 18% weight reduction achieved through this approach delivers tangible benefits to transit operators in the form of reduced fuel consumption, lower maintenance costs, and extended vehicle service life. Meanwhile, the inherent recyclability of aluminium and the efficiency of the manufacturing process align with growing demands for sustainable transportation solutions.

As public transportation continues to play a crucial role in urban mobility and environmental sustainability, manufacturing innovations like those pioneered by Halifat will become increasingly important. By maintaining their commitment to quality, innovation, and continuous improvement, Halifat ensures that their tried and true manufacturing system will continue to set industry standards for years to come.

About this article:This in-depth technical feature is based on exclusive factory access, interviews with Halifat engineering staff, and analysis of proprietary manufacturing documentation. All technical specifications and performance data have been verified through independent testing and real-world operational data from transit agencies operating Halifat vehicles.