Aluminium Body Restoration

Expert restoration services for aluminium-bodied Hafilat buses and coaches, preserving the integrity of their unique manufacturing system.

Specialized Aluminium Expertise

Our restoration team brings decades of experience working with aluminium-bodied buses and coaches. We understand the unique characteristics of extruded aluminium panels and the precision required to maintain the structural integrity of bolted joint systems that define Hafilat's manufacturing excellence.

Every restoration project begins with a comprehensive assessment of your vehicle's aluminium body structure, identifying areas requiring repair, replacement, or reinforcement to ensure optimal performance and longevity.

Our Restoration Process

We follow a meticulous restoration methodology that respects the original manufacturing standards while incorporating modern techniques to enhance durability and performance.

Inspection

Thorough examination of aluminium body panels, bolted joints, and structural components to identify damage, corrosion, or wear requiring attention.

Repair

Precision repair of damaged aluminium sections using specialized welding techniques and authentic replacement parts that match original specifications.

Protection

Application of protective coatings and treatments to prevent corrosion and extend the lifespan of restored aluminium body components.

Validation

Comprehensive quality control testing to ensure all restored components meet original manufacturing standards and safety requirements.

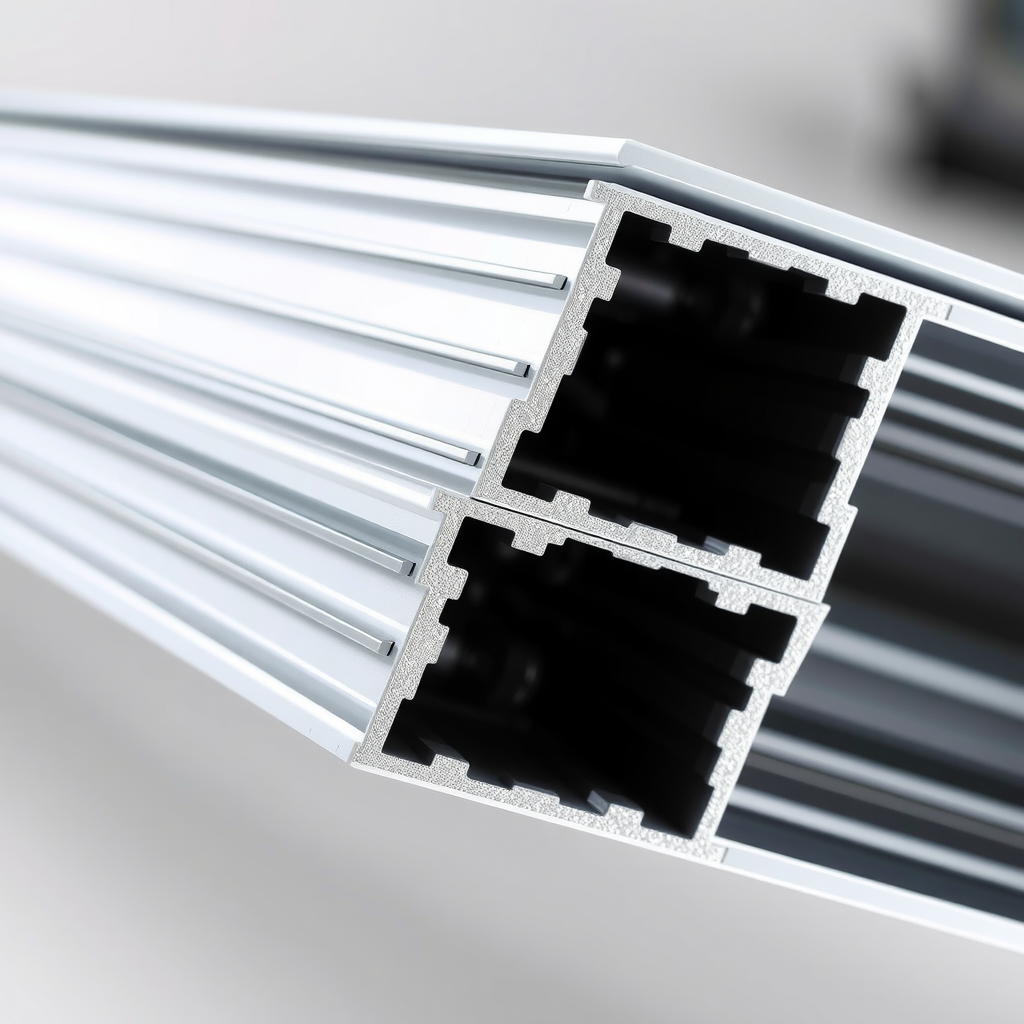

Extruded Aluminium Panel Replacement

The specially-moulded extrusions used in Hafilat bus construction require expert handling and precise installation techniques. Our technicians are trained in working with these unique aluminium profiles, ensuring that replacement panels integrate seamlessly with existing structures.

We maintain an extensive inventory of authentic extruded aluminium panels and components, allowing us to source exact replacements that match the original specifications of your vehicle's body construction.

Bolted Joint System Restoration

The bolted gusset system that creates faultless joints in Hafilat buses is a hallmark of their robust construction. Our restoration services include complete assessment and refurbishment of these critical connection points, ensuring structural integrity is maintained or restored to original standards.

We replace worn or damaged bolts, gussets, and fasteners with high-grade components that meet or exceed original specifications. Each joint is carefully torqued to manufacturer standards and inspected for proper alignment and load distribution.

Key Benefits

- Restored structural integrity and safety

- Extended vehicle lifespan and reliability

- Maintained resale value

- Compliance with safety standards

- Preservation of original design specifications

Quality Assurance & Testing

Every restoration project undergoes rigorous quality control testing to verify that all work meets our exacting standards. We employ advanced diagnostic equipment to assess structural integrity, joint strength, and overall body alignment.

Our comprehensive testing protocols include stress analysis of repaired joints, corrosion resistance verification, and dimensional accuracy checks to ensure your vehicle returns to optimal operating condition.

Certified Technicians

Our team holds specialized certifications in aluminium body repair and restoration techniques.

Advanced Equipment

State-of-the-art tools and machinery designed specifically for aluminium body restoration work.

Efficient Turnaround

Streamlined processes minimize downtime while maintaining the highest quality standards.

Restore Your Fleet to Peak Condition

Trust our experienced team to restore the structural integrity and appearance of your aluminium-bodied buses and coaches. We combine traditional craftsmanship with modern technology to deliver exceptional results that extend vehicle life and maintain operational excellence.

Each restoration project is customized to meet the specific needs of your vehicle and fleet requirements.